Today

Porsche Engineering ─ the engineering services provider for future-oriented mobility. The company therefore approaches the technical challenges from a wide range of projects in an accordingly holistic and innovative spirit. Always the top priority: a lean, sustainable and efficient approach to finding the solution and conducting development work. Whether it is the outstanding skill in the field of electromobility that Porsche Engineering demonstrated in 2014 in developing the battery for the Porsche 919 Hybrid, our exceptional expertise in the areas of lightweight construction and downsizing or our outside-the-box thinking in the development of a hospital bed or outdoor barbecue ─ the engineers from Porsche Engineering always bring the same dedication to the highest quality, forward-looking concepts and custom solutions.

2016 – Founding of Porsche Engineering Romania SRL

With the foundation of Porsche Engineering Romania, the company aims to further expand the competences in the area of Digitization. With Cluj-Napoca, Porsche Engineering established a subsidiary in a university city that holds a very special start-up atmosphere and also belongs to the most innovative regions in the area of software development within Europe. For Porsche Engineering, this city offers the ideal conditions for innovative software development for the automotive industry. In the following years, Porsche Engineering Romania SRL wants to focus on the recruitment of first-class software engineers that can be found in the region of Cluj-Napoca.

2014 - Founding of Porsche Engineering (Shanghai) Co., Ltd.

Porsche has a long tradition of development for Chinese customers. With the founding of the subsidiary in Shanghai, Porsche Engineering expanded on its years of engagement in China. One important component is the collaboration with Tongji University in Shanghai, which was bolstered by an official cooperation agreement in 2014. The deal intensifies an already fruitful exchange with regard to science, research, instruction, testing facilities and engineering. For Porsche Engineering, another piece in the puzzle towards comprehensive coverage of customer projects in the region.

2014 - Return to the Endurance Classic Le Mans

After 16 overall victories followed by 16 years away from the race, Porsche returned to Le Mans, the most renowned endurance race in the world, with the innovative 919 Hybrid. Drawing on its many years of experience in the field of battery technology, Porsche Engineering developed the battery for the new LMP1 prototype from Porsche ─ from the mechanical structure to complete system control and testing.

2012 - Porsche Engineering Takes Over Nardò Technical Center

With the Nardò Technical Center (NTC) in the southern Italian region of Apulia, Porsche acquired one of the most renowned automobile testing grounds in the world. The testing facility has been operated under the aegis of Porsche Engineering ever since and comprises a 6.2-kilometer handling course, the world famous 12.6-kilometer circular track as well as dynamics courses, acoustic and off-road tracks and numerous workshops. The testing grounds remain available for a wide range of vehicle testing purposes by the international automotive industry.

2011 - Boxster E Research Project Introduced

With the “Boxster E” lab vehicle, Porsche Engineering demonstrated its deep and diverse experience in the field of electromobility. The purely electric powertrain has two electric motors with up to 180 kW of output and a high-voltage battery for 240 kW. That makes for typical sports car-type performance. The central battery management system secures the system and can handle rapid charges taking less than 30 minutes. These are all the fruits of Porsche Engineering's wealth of electromobility experience.

2011 - 80 Years of Engineering Services

In 2011, Porsche’s engineering services celebrated an anniversary: Over a period of 80 years, Porsche has earned its reputation as one of the most renowned and multifaceted engineering services providers in the world. The tradition of engineering services started by Ferdinand Porsche in 1931 is successfully carried on today by the Porsche Engineering Group GmbH headquartered in Weissach.

2002 - A Revolutionary Engine for Harley Davidson

Under the code name “Revolution Engine”, in 2002 development partner Porsche Engineering developed a new V2 engine for the “V-Rod” model of the American motorcycle manufacturer Harley-Davidson. Porsche engineers constructed a water-cooled 1,131 cc motor based on a racing engine that delighted Harley-Davidson's demanding clientele both for its performance as well as its imposing sound.

2001 - Formation of the Porsche Engineering Group

In 2001, the Porsche Engineering Group GmbH headquartered at the Development Center in Weissach was founded as the central holding company for Porsche's rich tradition of engineering services. The resulting tight networking of the Porsche Engineering locations at home and abroad with the Porsche Development Center in Weissach and the efficient exchange of information in the project teams enables the Group to provide the requisite coordination and provide a foundation for the networking and lateral thinking that ensures smooth and successful execution of customer projects.

2001 - Founding of Porsche Engineering Prague

The Czech location of Porsche Engineering is specialized on complex technical calculations and simulations which make a significant contribution to the internationally integrated engineering services of Porsche. The staff in Prague work closely with colleagues at all other locations. The founding of Porsche Engineering Services, spol. s r.o. was closely linked to the collaboration with the Czech Technical University in Prague which has been in place since 1996.

1996 - Founding of Porsche Engineering Services GmbH

With the founding of Porsche Engineering Services GmbH in October 1996, the storied tradition of engineering services by Porsche at last got its own legal entity. Since that time, the Bietigheim-Bissingen location has been an important center for the project teams of Porsche Engineering.

1996 - Cooperation Agreement with Czech Technical University in Prague

Porsche Engineering and the Czech Technical University have collaborated in the field of technical calculation and simulation since 1996. This bridge between industry and academic research and instruction has resulted in a fruitful and mutually beneficial exchange.

1994 - Vehicle Study for the Chinese Market

At the Beijing International Family Car Congress, Porsche presented the C88 study, which was developed especially for the Chinese market. The automobile catered to the needs of Chinese customers and was designed in three versions: In addition to an extremely affordable, two-door version, a standard and four-door notchback luxury version were also planned. The development goals were simple manufacturing methods, a high quality standard and high level of vehicle safety.

1990 - Premium Model Mercedes-Benz

Daimler-Benz AG commissioned Porsche to do the design and testing for series production of its W 124 sedan with a 5-liter V8 four-valve M 119 engine. Series production including mounting the bodyshell and final assembly also took place at Porsche’s plant in Stuttgart-Zuffenhausen.

1983 - A Formula 1 Racing Engine for the Podium

Commissioned by the British racing team McLaren and financed by the Saudi businessman Mansour Ojjeh, Porsche developed the TAG turbo engine for the McLaren MP4 Formula 1 race car. The 1.5-liter turbocharged V6 engine delivered up to 1,000 HP. With a total of three World Championships, the “TAG turbo made by Porsche” became the dominant Formula 1 engine in the years 1984 to 1986.

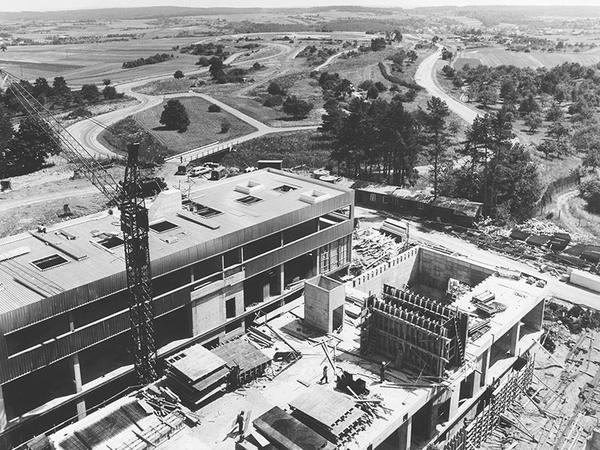

1961 - Laying of the Foundation Stone for the Weissach Development Center

In 1961, Ferry Porsche laid the foundation for the Weissach Development Center, 25 kilometers north-west of Stuttgart-Zuffenhausen. He later had a “skid pad” built for chassis testing that is still used today. The 1970s and 1980s saw the addition of an extensive test course and elaborate installations such as a wind tunnel, crash facility, exhaust gas testing center and a range of engine test benches. Over the years and continuing today, the Weissach Development Center has been continuously expanded such that today, with its highly innovative testing facilities and test tracks, the center is regarded as a hot-spot in the world of engineering. Then, as now, these facilities are available to external customers as well through Porsche Engineering.

1948 - Porsche 356 ─ Birth of the Porsche Sports Car Brand

In July 1947, the Porsche engineering office started work under its own steam on the Type 356 VW Sports Car. Based on previous designs like the Volkswagen or the Type 64 Berlin-Rome racing car, the design concepts with the internal construction number 356 was realized in spring 1948. After the prototype Porsche 356 bearing chassis number 356-001 completed its maiden trip on 8 June 1948, it was granted a special road permit from the state government of Carinthia. It marked the birth of the Porsche sports car brand.

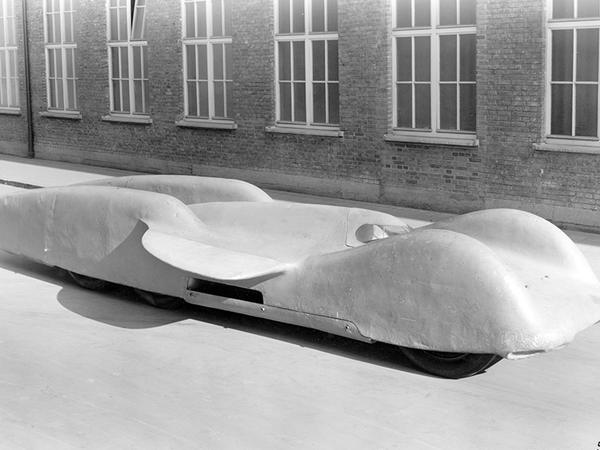

1937 - A World Speed Record Car and a Tractor

For Daimler-Benz AG, Porsche not only developed technical engine components for the Mercedes Silver Arrows, but also designed the Type 80 World Speed Record Car from 1937 to 1939. At the same time, Ferdinand Porsche and his engineers developed the Type 110 compact tractor for farm use with an air-cooled two-cylinder power unit. The model laid the foundation for the subsequent “People’s Tractor” and the Porsche diesel tractor built after World War II.

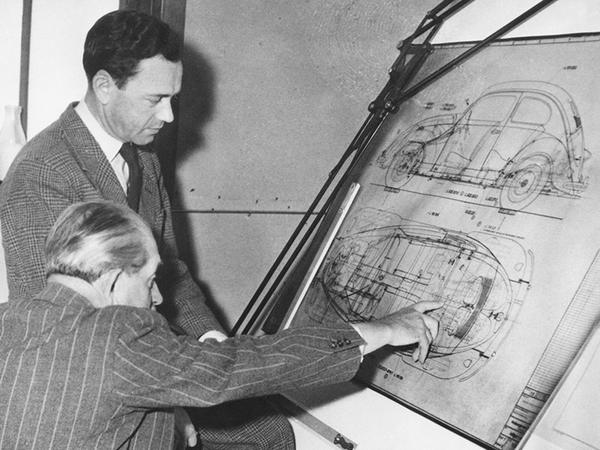

1934 - Development of the “Volkswagen”, One of the First Major Projects

The impetus for the design of the now world-renowned Volkswagen “Beetle” came in 1934, when the “Reich Association of the German Automobile Industry” commissioned Ferdinand Porsche to design and build a German Volkswagen or “People’s Car". In the design of the Volkswagen, Ferdinand Porsche and his engineers envisioned a newly developed, air-cooled four-cylinder flat engine and body. The result was used not only millions of time in the VW Beetle, but from 1948 also as the drivetrain basis of the legendary Porsche 356.

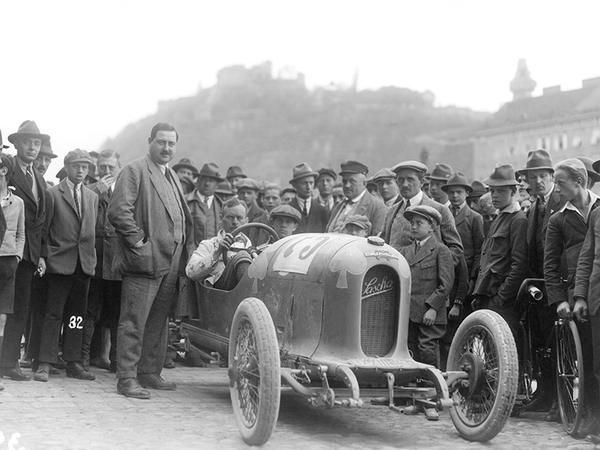

1906 - First Racing Victories in Preparation

An important milestone in Ferdinand Porsche’s career came in 1906. At a mere 31 years of age, he assumed the position of the Technical Director at Austro Daimler in Wiener Neustadt and was in charge of products from one of Europe's leading automobile companies. The “Prince Henry Car” that led the Austro-Daimler plant team to finish in the top three at the widely known Prince Henry Trials was among the greatest achievements of this time. With Austro-Daimler’s “Sascha” model, he developed a small racing car that prevailed in the Targa Florio race in 1922 against competition with a greater engine capacity and notched up no less than 43 race victories.

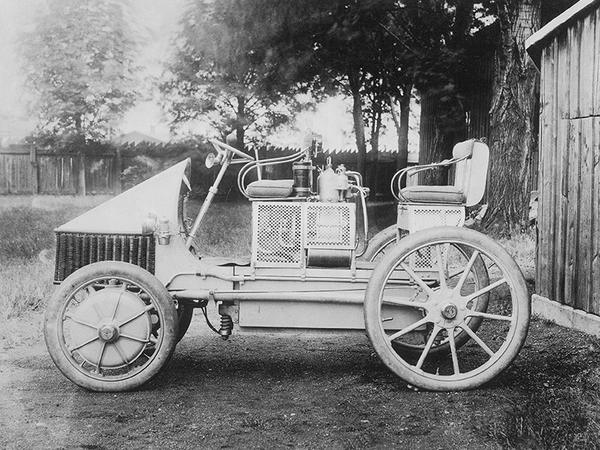

1900 - Porsche Becomes a Pioneer in Electromobility

The first result of Ferdinand Porsche's work in automobile development was an electric car called the “Lohner Porsche”, which was powered by wheel-hub motors, and attracted attention at the Paris World Fair in 1900.